Switch boxes are one of the most crucial devices that help to handle and maintain electric flow at your home or office. Switch box moulding is the process of creating these boxes which are available in a million shapes and sizes. We will talk about the switch box, why making them well is important as being precise in its production process and benefits of using good quality materials all this to make it work better for you longer see some new concepts thinking how we can still improve our switch boxes with new ideas like Electronic mould from TQ.

Well-designed switch box will be easy to operate, relatively safe and heat resistant. When discussing accuracy, it suggests that the dimension of opening box ought to be proper size and shape. All of this is true, among other tiny things such as screw holes being that much more important to be in the right place like tray mould resin from TQ. If this info is wrong it may result in the switch box not working properly and that can cause problems.

Good materials will also more often than not make it easier to add intricate and complex designs for switch boxes. During the injection moulding process, Thermoplastic mould from TQ can handle the high temperatures and pressures better than other materials. This consequently ensures that the switch box is perfect all time on every occasion in accordance with specs we demand.

Switch box mould are another type of production that needs to be durable and work method. Since switch boxes are manufactured to be durable, the molds used in their manufacturing should also last long even with extensive usage. Since safety and reliability is the top priority for a manufacturing hub, they need to assure that every switch box like Auto mould produced must be exactly in similar look with other components which makes consistency very important.

Moulds also need proper maintenance and care to ensure they last longer. Whether this is cleaning, evaluating for damage or the sort and to place any sign of deterioration part like any Household mould.

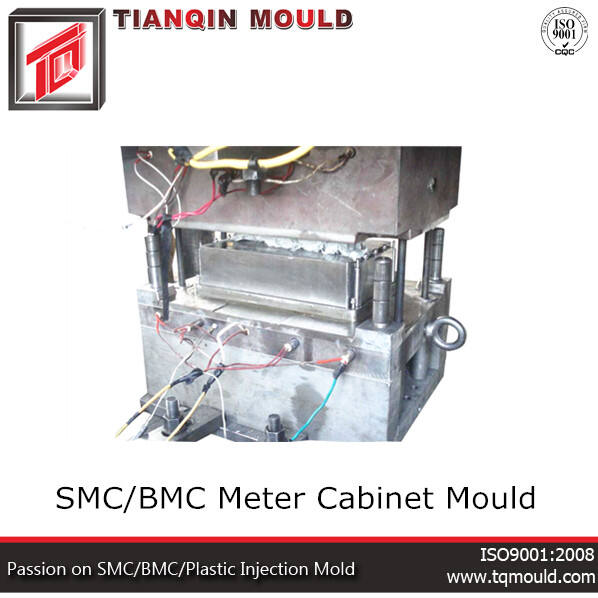

Tian Qin develops different plans for each project to ensure quality and production as quickly as possible. We will make use of professional equipment prior to delivery to test the Switch box mould as well as the structure to ensure that the customer receives the items in perfect order.

The company holds ISO, CE and many other certificates. The warranty for the company is 12 months, Switch box mould from the date the customer receives the product. However, we'll be able to resolve after-sales problems even if the issue is beyond 12 months.

TianQin is home to its Switch box mould workshop that covers more than 8,000 square metres as well as the processing equipment it owns, and a experienced team that has been deeply cultivated in the field of moulds over the past 20 years, and has unique insights on mould design and manufacturing, as it can provide clients with the ideal solution.

TianQin currently offers moulds and Switch box mould. There's no limit to the product categories, and the highest level of support for a custom design and customized solutions. Make sure that customers get a unique designs and the highest capacity output.