News

-

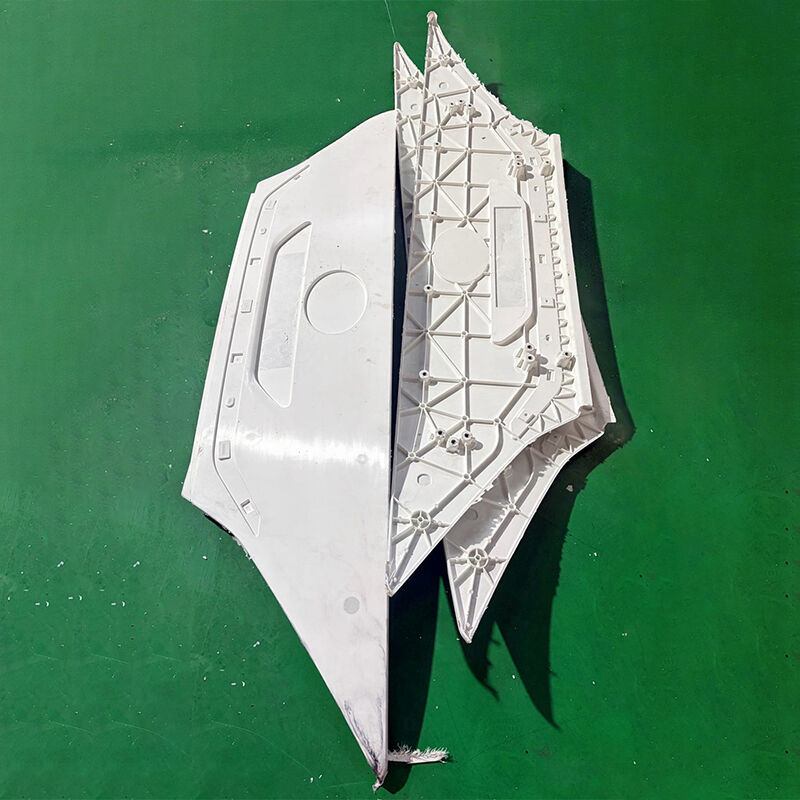

Latest Mold Updates: Industrial Cooler & Auto Parts from Huangyan, Taizhou

As China’s "Hometown of Moulds", Huangyan’s mold factories have launched impactful upgrades, focusing on industrial cooler and auto parts molds amid the region’s vertical integration strategy. For industrial coolers, the new SMC ma...

Jan. 07. 2026 -

TIANQIN’s team in Turkey for the 2025 EURASIAN COMPOSITES SHOW (November 26-28, 2025)

I. Exhibition Overview: The EURASIAN COMPOSITES SHOW, organized by ARTKIM Fuarcılık, is the first event dedicated to the composite materials industry, uniting representatives from the Middle East, Eastern Europe, North Africa, and the Balkans. Held b...

Dec. 09. 2025 -

TIANQIN’s team in Paris for Milipol Paris 2025

Milipol Paris, the leading event for Homeland security and safety, is organised every two years under the aegis of the French Ministry for the Interior, in partnership with several national and international institutions / governmental bodies. In 202...

Nov. 26. 2025 -

UHMWPE Fiber: A Core Strategic Material Empowering High-End Manufacturing in China

As the third-generation high-performance fiber following carbon fiber and aramid fiber, ultra-high molecular weight polyethylene (UHMWPE) fiber has become a key strategic material explicitly identified in Made in China 2025, thanks to its core advant...

Nov. 13. 2025 -

Several Manufacturing Methods of Composite Bulletproof Helmets

Exploring Composite Bulletproof Helmets: Multiple Processes Unlocking Superb Protective Capabilities. Composite Bulletproof Helmets: A Solid Defense Line for Safeguarding Lives. Briefly elaborate on the important role of composite bulletproof helmets...

Nov. 08. 2025 -

How to Improve the Anti-Dent Performance of Bulletproof Helmets

Core Definition of Anti-Dent Performance and Industry Standards The anti-dent performance of a bulletproof helmet refers to the ability of the helmet’s shell and inner liner to avoid permanent dents when subjected to high-speed impacts (e.g., f...

Nov. 05. 2025 -

How to Improve the V50 Value of Bulletproof Helmets

Core Definition and Industrial Significance of V50 Value The V50 value (Velocity at 50% Probability of Penetration) is a key indicator for measuring the protective performance of bulletproof helmets. It refers to the average velocity at which a proje...

Nov. 01. 2025 -

Manufacturing Process of Seamless Bulletproof Helmets

Process Overview The core advantage of the seamless bulletproof helmet manufacturing process lies in eliminating the traditional cutting procedure. By adopting integrated molding technology, it maintains the integrity and continuity of core materials...

Oct. 24. 2025 -

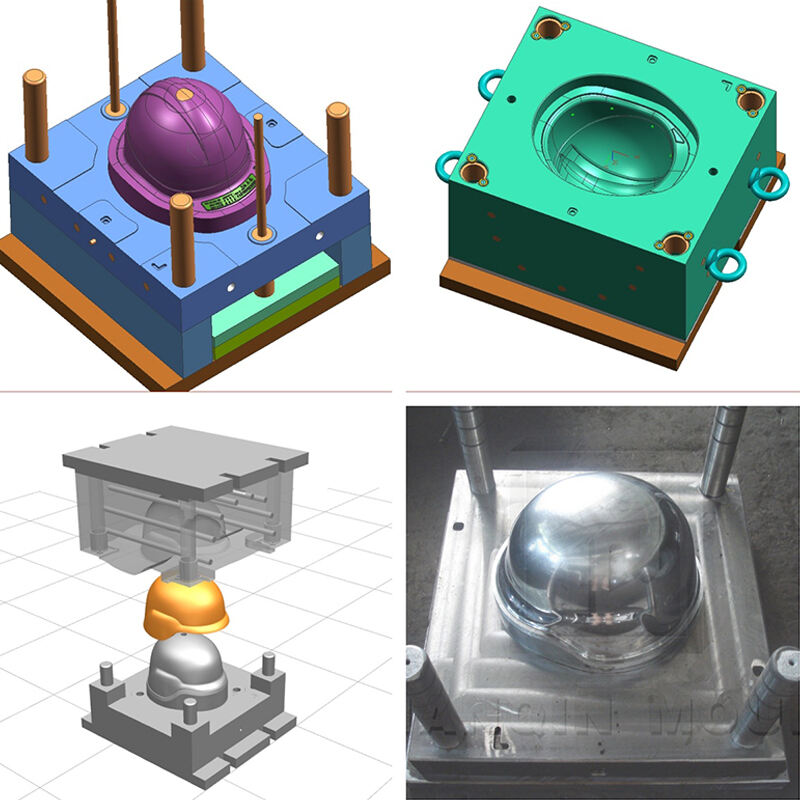

Manufacturing Process of Bulletproof Helmets

I. Raw Material Selection: Laying a Solid Foundation for Safety The protective performance of a bulletproof helmet begins with raw material selection at the source, where each type of raw material undergoes rigorous multi-dimensional screening. The c...

Oct. 13. 2025 -

Production Process of Aramid Bulletproof Helmets

With high-strength aramid fibers as the core, aramid bulletproof helmets are high-safety equipment featuring light weight and high protection, manufactured through multiple precision processes. Every step, from raw material processing to finished pro...

Sep. 24. 2025 -

The Quality and Manufacturing Process of UD-PE Nonwoven Fabric

The quality foundation of UD-PE (Unidirectionally Drawn Polyethylene) nonwoven fabric originates from the strict selection of ultra-high molecular weight polyethylene (UHMWPE) chips. Raw materials with stable melt flow rate and uniform molecular weig...

Sep. 10. 2025 -

SMC product hydraulic press selection

In the field of industrial production, the hydraulic press is a crucial piece of equipment, how to choose? Clarify the use requirements and scenarios When choosing a hydraulic press, you must first clarify your own use needs and scenarios. 1. Process...

Aug. 13. 2025