Do you know the existence of a dedicated machine known as an SMC molding machine? (The acronym SMC stands for Sheet Molding Compound.) This is the stuff they use to build stuff that is both strong and light. Shaping this material into a number of different shapes is then accomplished by smc molding processs. Let’s find out how that machine is put together and why it is critical in a world of stuff.

SMC molding machines are designed to allow companies to formulate products quickly and easily. These machines can be fast and produce quality results. Businesses also save time and money with SMC molding machines. That allows them to produce more products in a shorter time frame, enabling them to cater to their customers.

One of the great advantages of SMC molding machines is the wide range of products they can produce. They can turn out tiny parts for machines or huge panels for cars. This capability of molding in different shapes and sizes makes SMC molding machines an excellent choice for many companies.

One of the largest consumers of SMC molding machines is the automobile industry. These machines produce parts for cars and trucks and other vehicles. The benefits of SMC moulding equipment in the automotive field are evident. They assist businesses in making parts fast and good. It means cars can be produced more quickly and cheaply, which is good for both the companies that make them and the people who buy them.

How SMC Molding Works Between the Parts & the Machine Now that we’ve outlined the parts involved in the SMC molding process with modern machines, it’s time to spread up the process to illuminate the interaction between them and see how everything comes together.

So, how does SMC molding work? The machine feeds from the raw SMC material, to begin. Then, the machine heats up the material and forms it into the required shape. The product then cools and is ejected from the machine. This happens over and over … and over again to produce lots of products fast. Today companies can produce strong, lightweight products extremely quickly with modern SMC molding machines.

The company has achieved ISO, CE and SMC molding machine. The warranty period for the firm is 12 months on the day the client receives the products. We will still respond positively to issues after-sales, even if a issue is beyond 12 months.

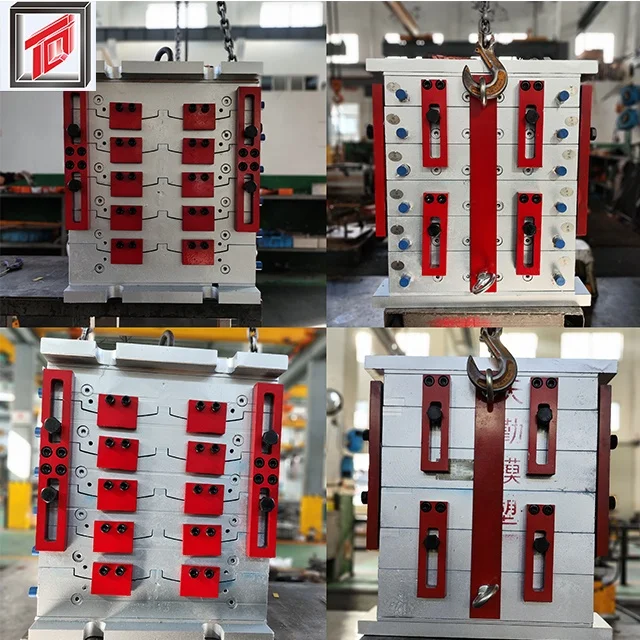

TianQin has its own workshop, which is 8,000 square metres and the SMC molding machine it owns and a expert team, that has been thoroughly trained in the field of moulds for over 20 years and has unique knowledge regarding mould design and production in order to provide customers with the most effective solution.

Tian Qin develops different plans for each project to guarantee quality and SMC molding machine within the shortest amount of time. Before shipping, we use professional equipment to ensure that the dimensions and design are correct to ensure that the client receives the product with no issues.

TianQin SMC molding machine offers molds as well as plastic items. The product categories are unlimited We provide the highest level of support for customized solutions and custom designs. Allow customers to have a distinctive designs and the highest capacity output.