Introducing, the TQ UHMWPE Armor Plate Mould Vest Plate Mould Compression Molding PE Armor Mold! This innovative product is changing the game in the world of armor plate manufacturing. The TQ brand is known for quality and durability, and this armor plate mould is no exception.

Made from ultra-high molecular weight polyethylene (UHMWPE), this armor plate mould is lighter and more flexible than traditional steel armor plates. This makes it more comfortable to wear for extended periods of time, without sacrificing protection. The UHMWPE material is also highly resistant to chemicals, making it an ideal choice for military, law enforcement, and security professionals.

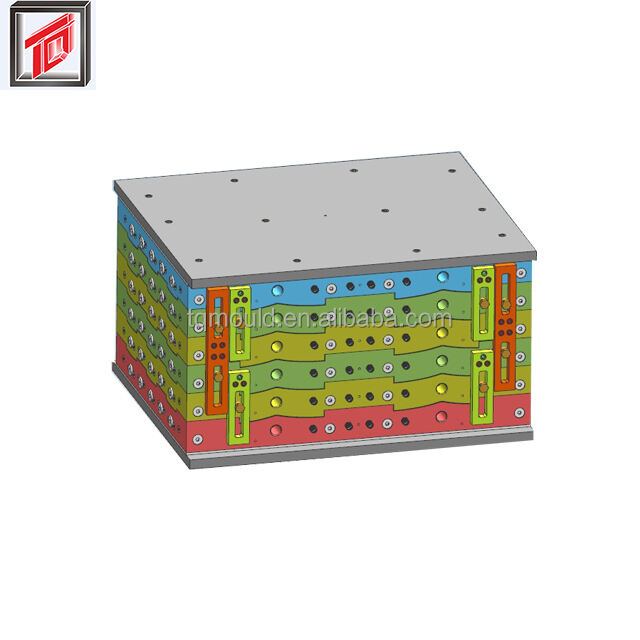

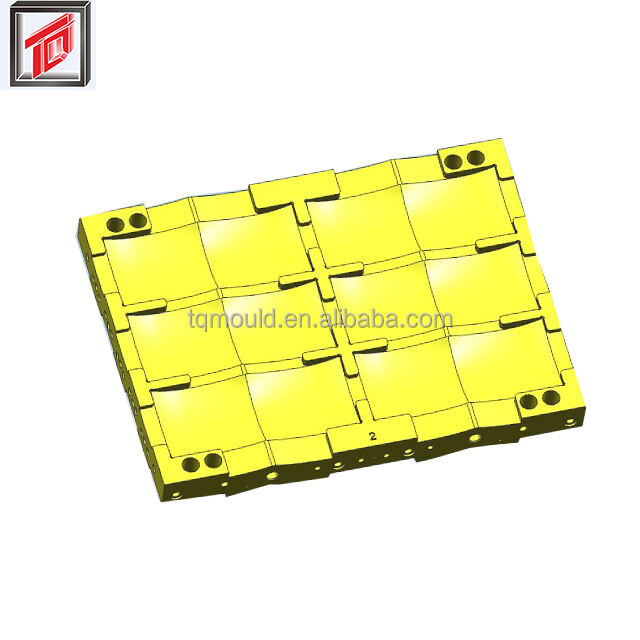

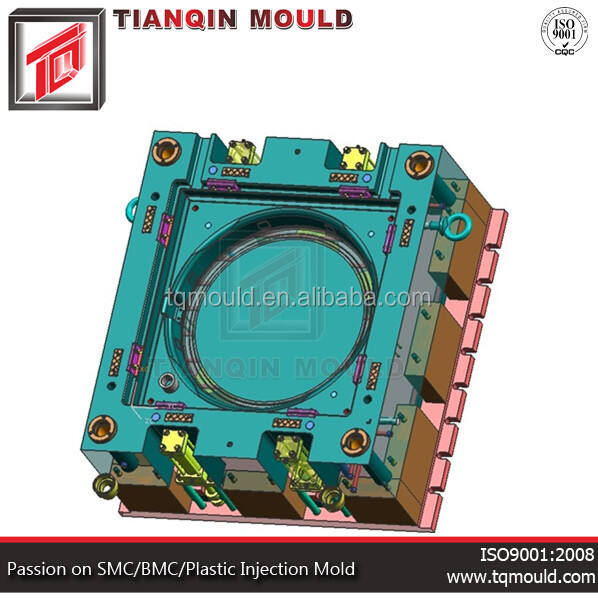

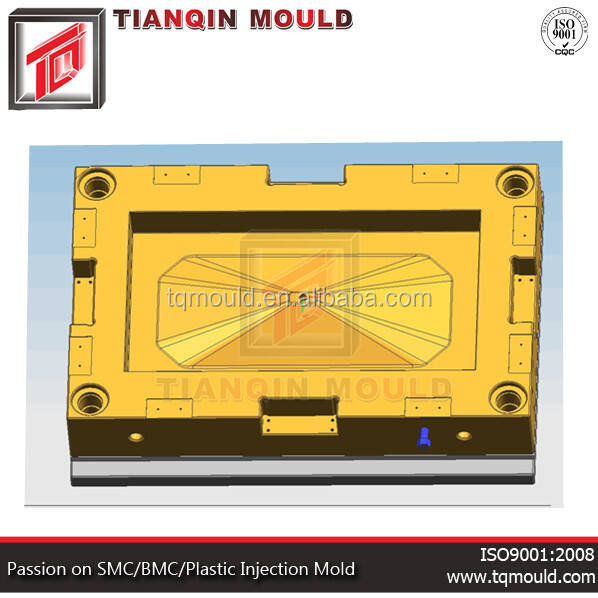

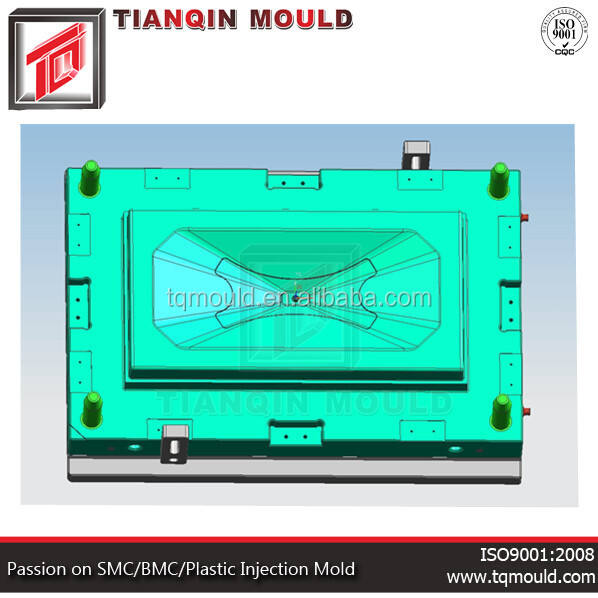

The compression molding process used to create this armour plate mould ensures a precise and consistent fit every time. This means that the armor plates produced from this mould will be uniform in shape and size, minimizing the need for adjustments or modifications. The TQ UHMWPE Armor Plate Mould Vest Plate Mould Compression Molding PE Armor Mold is designed to produce armor plates that meet or exceed industry standards for ballistic protection.

Whether you are looking to outfit your tactical team with the latest in protective gear, or are in need of armour plates for personal use, the TQ UHMWPE Armor Plate Mould Vest Plate Mould Compression Molding PE Armor Mold is the perfect solution. This mould is easy to use and produces high-quality, reliable armour plates every time.

Don't settle for inferior armour plate moulds that may fail when you need them most. Choose the TQ UHMWPE Armor Plate Mould Vest Plate Mould Compression Molding PE Armor Mold for top-of-the-line protection and peace of mind. Order yours today and experience the difference that quality craftsmanship and materials can make in your safety and security

Taizhou Tianqin Mould & Plastics Co., Ltd

UHMWPE Armor Plate Mould Vest Plate Mould Compression Molding PE Armor Mold Manufacturer

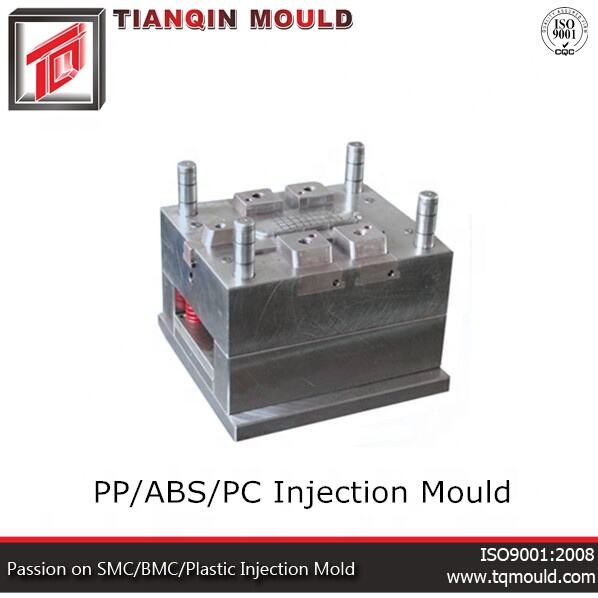

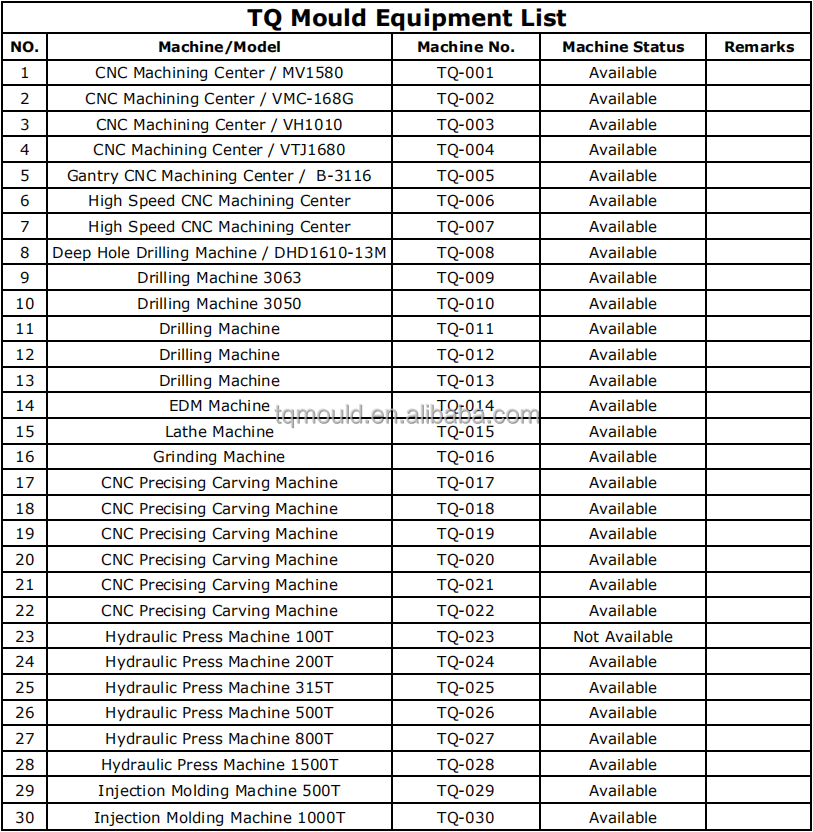

With over 15 years OEM & ODM experience, TQ Mould Co., Ltd. Is a professional manufacturer and exporter in zhejiang Taizhou Huangyan, We export not only abroad but also domestically. Specialized in designing and manufacturing high-quality plastic injection mould. More than 25 sets of equipment for mould processing, manufacturing, trial and parts production

Including Milling Machine, Cutting Machine, CNC Machine, EDM Machine, Grinder Machine, Drilling Machine, Hydraulic Press Machine, etc

We can also provide 3D design, mold making and bulk production service for your company

Main Compression and Injection Mould Category:

1. Auto parts mould: heavy-duty truck bumper, instruments panel, car roof, door panel, trunk cover, sky shade, engine hood, air conditioner shell, battery box, etc

2. Kitchenware & sanitary ware mould: bathtub, shower room, shower tray, waterproof plate, toilet lid, sink, table top, melamine tableware, etc

3. Electronic appliance mould: electric switch box, power distribution box, electric fan cover, meter box, cable branch box, cable holder, insulator, insulating cover, etc

4. Sports equipment mould: basketball board, table-tennis table board, FRP chair, etc

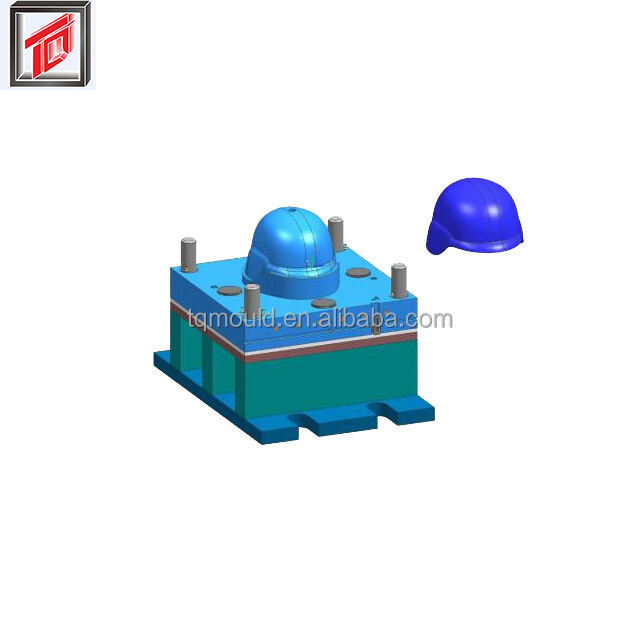

5. Products mould: helmet, armor, shield (PE, Kevlar), magazine, etc

6. Other construction & industrial supplies mould: water tank, manhole cover, trash can, dustbin, industrial helmet, etc

| Name | Description |

| Mould Material | 45#/ 50# /P20 /H13/ S136 /SKD61/ etc |

| Cavity | Single/ Multi |

| Runner | Cold / Hot |

| Design Software | UG / CAD / PORE /ect |

| Mould Life | 10,0000 - 1,000,000 shots |

| Delivery Time | 35-50 days |

| Specification | As the client's requirements |

Q1: Could we get the sample for reference

A1: Glad to send samples for your inspection, but need to pay the sample (depends on product's value) and the express fees, hope understand

Q2: How long the product will be ready for shipment

A2: Depends on the product's specification and quantity. The time of delivery is different. In general it will take 35-45 work days

Q3: How can we guarantee quality

A3:

(1) Strict detection during production

(2) Strict final inspection on products before shipment and intact product packaging ensured

Q4: What is your terms of payment

A4: T/T, L/C, PayPal, and can be negotiated

Q5:How to solve the quality problems after sales

A5:

(1) Take photo or video about the problems and send to us.

(2) Send back the defective products to us if necessary. Feedback the solution to you once confirmed

Q6: Can we make our logo on the products

A6: Sure. Please contact us, we will reply within 12 hours. Thank you very much

Our professional sales team is always waiting for your consultation.