TQ’s UHMWPE plates make a lot of things better and safer. I discuss further below a couple of the places these plate mould are extremely useful: heavy industrial floors and medical device manufacturing.

What Makes UHMWPE Plates Perfect for Heavy-Duty Industrial Flooring Uses?

Think of a warehouse where forklifts shift pallets all day. The floor can't get torn up easily or cause the machines to slip. UHMWPE plate resin mold are greasy good not as in a joke bad way, but actually slippery in a material physics good way: that type of slippery where they abide by the minimum hand natural state rule for lubricating anything from clenching machine parts to sliding against stuff.

UHMWPE Plate Moulds and How They Can Optimize Medical Device Production

Manufacturing medical devices requires parts that are highly precise and clean. Plate molds made with TQ UHMWPE make doing this much easier since it can be formed into virtually any shape. When those resin plate molds are used to make a mold, it never gets scratched or marred so the devices that are made with it always fit perfectly. Medical devices such as surgical and diagnostic machines require parts that move without friction and won’t wear out rapidly.

Where to Purchase Wholesale UHMWPE Plates for High End Engineering Projects?

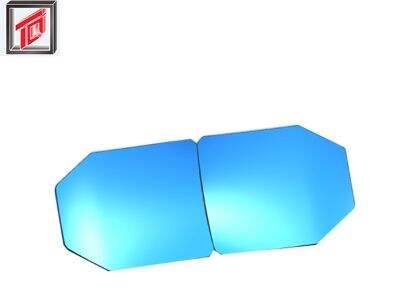

If you are looking for tough plastic plates, to build or repair industrial machines, why not use UHMWPE plates. UHMWPE is short for Ultra-High Molecular Weight Polyethylene. It is a hard and slippy plastic that can take heavy use without being broken or worn out easily. If you have a large project and need lots of plates, other types or in other sizes as well, wholesale shopping is the best option to cut down on costs and all the materials you need at once.

How to Choose the Appropriate Thickness of UHMWPE Plate for You For general applications?

The selection of the right thickness types of UHMWPE plates is paramount to ensure that they will perform as required for your particular application. UHMWPE plates are available in a wide range of thicknesses, some extremely thin and others very thick, each serving different purposes. At TQ, we would like to help you choose the ideal thickness so your plates last long and do what is needed. If you only need plates for light uses, such as lining a small chute or protecting an area from scratch marks, thinner plates could suffice.

What are the major advantages of using UHMWPE Plates in Food Processing?

Like we said before, using UHMWPE plates in food processing equipment is a great idea and here why; it has many advantages that ensure your food is safe and machines operate efficiently. The UHMWPE is a special plastic that does not absorb water or food and stays sanitary, preventing bacteria growth. This was the most important factor in food applications which need to be cleaned regularly.

Table of Contents

- What Makes UHMWPE Plates Perfect for Heavy-Duty Industrial Flooring Uses?

- UHMWPE Plate Moulds and How They Can Optimize Medical Device Production

- Where to Purchase Wholesale UHMWPE Plates for High End Engineering Projects?

- How to Choose the Appropriate Thickness of UHMWPE Plate for You For general applications?

- What are the major advantages of using UHMWPE Plates in Food Processing?