The market for defense parts is transforming rapidly. That means military necessities (like rugged vehicles, accurate weapons and reliable communication devices) drive manufacturers to manufacture better and smarter products. New mold technologies are enabling Military moulds to be built that last longer, and work better. At TQ, we know how these tools unlock doors to thrilling change. Stuff that was difficult or cumbersome before is now fast and easy. You’re not just making parts; you’re making the future of defense with smart ideas and careful work.

What New Developments Are Influencing Defense Component Production?

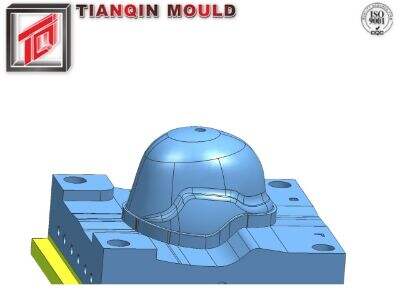

Defense component manufacturing isn't what it used to be. The traditional means of forming metal or plastic parts are being replaced by tools and techniques that are smarter, faster, more efficient and even cheaper. Key to making these more challenging pieces, which require both very high resolution and production speeds, is advanced mold machines. These machines can take on intricate shapes that fit seamlessly in harsh environments like battlefields. A mould, for instance one that forms an armor plate, must be precise because even a tiny mistake can lead to failure in use. Materials used today are also stronger and lighter, so that the moulds have to be designed conscientiously for processing such new materials. We have shoe lasts that are compatible with special metal alloys and reinforced plastics at the TQ. This makes the parts not only more robust but lighter, contributing to faster and safer movement of soldiers.

Another important innovation is automation. Now robots and computer controls help make parts with few human errors. This makes for a faster operation, and it helps maintain quality. But automation is not only about speed. It also affords the opportunity to exercise parts during production. If a component has a sliver of an imperfection, the system can detect it and rectify the problem early. That saves time and cost, something that’s very important when you’re making thousands of parts. For that matter, massaging the mold design a bit based on trial results can often make all the difference in how well the part functions. TQ’s staff is used to tweaking designs on the fly as part of that feedback loop, so each batch meets military standards.

Occasionally, new technologies can appear complex to the point of being confusing, but their purpose is clear: make better parts more readily and more affordably. 3D printing, for instance, is used to make mould prototypes fast. It enables engineers to experiment with new ideas without having to wait months for a factory to finish building a mould. This trial-and-error process equates to better end products and less wastage. At TQ, we combine traditional skills with these tools to good effect. We understand that just because it is new, doesn’t mean we forget the old. This means layering on new levels of precision and care.

How Can New Military Mould Technologies Support Quality Products when Ordering bulk Items?

When the military is buying a lot of parts, quality cannot fall to the wayside. And bulk orders are tricky, because when you’re making thousands of a part, little mistakes can snowball into big problems. Modern mould technology goes a long way towards addressing this problem by ensuring that every part is made as near to perfect as it can be. TQ knows the importance of maintaining quality as consistent as possible, even on thousands of pieces or more. We also use tray moulds that are longer lasting, easy to clean or repair if necessary. as a result that we get consistent output every time.

One of the ways that mould technology contributes to higher quality is with improvements to heat control. Warping or other damage may occur when a mold is filled with hot flowing metal or plastic. New moulds come with cooling channels that maintain a constant temperature. This also means no shrinking or cracking of parts. Think of creating thousands of connectors for a radio system. Even a few warping can result in communication failure. TQ’s molds are designed to prevent that, so every piece is flawless.

Another factor is surface finish. Certain military parts require a smooth surface to function properly or to fit with other parts. Polishing and special coatings are among new mould designs that ensure surfaces are flawless. Not only will this offer better performance, but the amount of work you have to do after casting it's function is less. Bulk buyers save both cost and time concerning this. We have put a lot of money into mould polishing technology because we know its importance for the end product.

In addition to the technical advances, smart moulds permit rapid alterations should purchasers want a small tweak. Standards for military projects, in particular, are often moved around as new threats or technologies emerge. Rather than casting a whole new mold, TQ’s designs consist of modular parts that can be swapped or modified in short order. This flexibility enables buyers to keep ahead without having to wait months for new parts. Being able to pivot on a dime is massively beneficial in defense manufacturing.

And finally, mould maintenance is a big thing. The moulds are maintained regularly as well and all the checks and repairs are carried out to keep them working like new. TQ provides customers with end-user support on bulk purchases, including care training and quick service. That means fewer delays, less waste. It’s not just in the making of moulds but sourcing guarantee they keep making good parts, day after day. For military consumers, reliability equals trust and safety when it counts most.

Why Are Military Moulds Important As High-Precision Defence Component Enablers?

These parts need to be very precise and strong because they are used in weapons, vehicles and other machines that help keep countries safe. A minuscule error in the processing of these elements can result in major problems, which is why the moulds must be flawless. Military moulds are used in shaping materials such as metal and plastic into the correct forms with minute attention to detail. That means every piece fits just right, and everything operates like you’d expect.

Our company, TQ, specializes in designing military molds that and are up to the standards just mentioned. We have unique designs and materials that can withstand extreme conditions. For instance, components formed by these moulds must withstand heat, pressure and wear during their service life. The moulds also need to be capable of making many similar components before quality starts to suffer. Which is important in the military, because everything has to work exactly the same when out in that field.

Military moulds have another benefit that must be discussed here – this type of mould can speed up the production process. Time is of the essence in defence industries. Moulds create the ability to manufacture many parts and do it fast. Which means that soldiers are getting their equipment without the sort of long delays. At TQ We make moulds that not only produce accurate parts, but help the factories run fast. Our molds minimize waste and decrease cost, a critical factor in keeping defense projects on budget.

In conclusion, military moulds are the crucible for producing high-precision defense components. It would be very difficult to develop safe and reliable equipment for the military without them. TQ’s commitment to quality and progress will guarantee these molds stand up against the rigorous requirements of the defense industry.

Military Mould Making and How New Technology Changes the Game

It’s not all fun and games when it comes to making military molds. Engineering quantum toolsDesign and production of these devices is full of complexity. One big challenge is that the parts produced by moulding have to be strong and durable. Military gear often operates in harsh conditions, say, in deserts or oceans or on battlefields, where normal parts would break down fast. So the moulds have to produce parts that can tolerate these extreme conditions.

Another question is that of the parts themselves. A few of the defense components have a complex shape and fine features. Designing molds capable of consistently making these complex parts is no small challenge. When the moulding is not perfect, you’re risking that a part will not fit or function properly and it could be hazardous.

Here at TQ, we solve these issues with new technologies. One powerful tool is computer-aided design, or CAD. CAD supports the engineers to design the mould on a computer before it is being produced. This means they can experiment with and refine the design without wasting materials. Another technology is 3D printing, where prototype mould parts can be produced rapidly. This can help spot errors early and accelerate the entire process.

What's New in Military Moulds for Better Durability and Performance?

The world of military moulds is a fluid one, because the requirements of defense are ever-evolving. The latest trends today involve creating moulds that last longer but also fabricate parts that do a better job in the field under harsh conditions. At TQ, we are constantly monitoring this evolution to deliver the latest and greatest moulds for our customers in the defense industry.

One of the steps in this direction is the introduction of high-performance materials. The making of molds is now being done from new kinds of steel and metal alloys. These materials are more resistant to wear and harder than previously. In other words, molds don’t deteriorate as quickly, even after creating thousands of parts. TQ select these materials in order that our moulds suitable for the tough requirements of military production.

Table of Contents

- What New Developments Are Influencing Defense Component Production?

- How Can New Military Mould Technologies Support Quality Products when Ordering bulk Items?

- Why Are Military Moulds Important As High-Precision Defence Component Enablers?

- Military Mould Making and How New Technology Changes the Game

- What's New in Military Moulds for Better Durability and Performance?