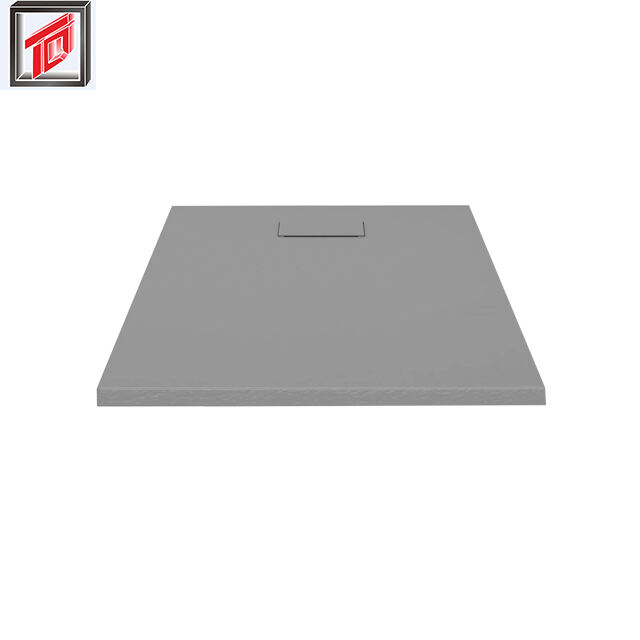

But when it comes to creating strong and reliable shower trays, the mould you use is absolutely key. This is where TQ steps in with our SMC shower tray moulds. Our moulds ensure that every shower tray comes out the way it is meant to, and helps make quality products. Next, taking a closer look at what makes our SMC shower tray moulds great for your production.

High Precision SMC Shower Tray Mould for Strong And Durable Production Mould Description No (1) Mould material 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.

At TQ, we have a premium range of SMC shower tray moulds. Constructed from high quality materials, they are built to last and withstand lots of use. In other words, less concern with breaking or replacing moulds and more time spent producing shower trays. The great thing about our moulds no more does a tray lack strength and look good, for production. Buyers will be happy because they have a good product that endures.

We understand that not all shower trays are created equal. thats why our SMC shower tray mould can be changed to meet what you need. If you need a large, small, deep or a shallow tray, we can modify our moulds to fit. With this personalisation you can create precisely the shower trays your customers desires. It’s like having a little magic wand that makes the perfect tray!

We use the most advanced technology to produce our SMC shower tray moulds. This tech ensures that every mold is the same and creates trays that are perfect. Honestly, we have very accurate machines and so every tray comes out looking neat and professional. With this high quality, businesses can rely on what they produce, assured that all trays meet high standards.

We get you’d like to keep costs down. That’s why we sale our SMC shower tray moulds at wholesale price. With our great pricing, you save up to thousands of dollars on your moulds, while still receiving high quality moulds. It's a win-win: you pay less and can still produce high-quality shower trays for your customers.

TianQin has its own workshop with 8,000 square metres and the processing equipment it owns, a expert team, that has been smc shower tray mould in the area of moulds for over 20 years and has unique insight in the design and manufacture of moulds in order to provide customers with the best solution.

The company has obtained ISO, CE and other certificates. The warranty for the company is smc shower tray mould starting at the time the buyer receives the goods. However, we'll continue to be responsive to issues after-sales, even if a problem exceeds 12 months.

smc shower tray mould will develop different plans for each different project to ensure that the product is of high quality and produced in the shortest amount of time. We will make use of professional equipment prior to shipping to examine the dimensions and the design to ensure that the customer gets the products in perfect condition.

smc shower tray mould offers plastic products and moulds. There's no limit to the categories of products, and the most comprehensive customer support is available for bespoke design and customized solutions. Customers can have a unique design and highest capacity output.