It has become very imperative to select the right materials when it comes to developing sturdy and secure structures. Sheet Molding Compound: Available in a Wide Range of Grades and Forms For builders, sheet molding compound – commonly known as SMC. It is inexpensive and versatile, meaning it can be used for a whole range of things – from cars to buildings (and literally anything else that humans need). In the subsequent portions, we will come to know why SMC is an excellent preference what stuff it is created from and in how many ways does plaster used as a construction.

SMC, as it is more commonly known, simply stands for sheet molded compound and is a composite material made from resins blended with fiberglass or other carbon reinforcing compounds. The blend is then formed into a solid piece through compression molding by pressing the mix together in a mold that both heats the mixture and exerts high pressure. But TQ SMC mould is unique thanks to the different components it's made from. For example, it's not just strong but lightweight and stiff. It becomes ideal for all types of construction with these properties. Also, SMC is corrosion-resistant and durable for a long time exposure to stresses in harsh conditions such as weathering or chemically.

Builders and manufacturers prefer SMC for many reasons. While Free is one reason why (another being its insane power). SMC can have high load capacities, that makes it ideal for creating bridges and tunnels as well as other structures where it is important the fact that they think secure enough to transport heavy loads. The lightweight nature of SMC is another advantage. This aides in minimizing the overall weight of the structure, thereby rendering it easier to transport and install at different places.

Apart from its mechanical properties and light weight, durability is one of most significant advantages in using SMC. This also makes it resistant to damage from the elements and chemicals, as well as UV rays. Therefore TQ SMC is a material that can potentially withstand the test of time, even in harsh environments where things wither away. SMC is also flexible allowing it to be used in a wide variety of shape and sizes for complex parts with low cost.

Sheet Molding Compound is used in nearly every construction application it seems. The most common usage is in construction of bridges. SMC is used in the creation of bridge decks, flat surfaces on which bridges are constructed for use by cars and pedestrians. The holes and chunks are then filled in with concrete which is also the material used to make up supporting structures for the bridge (like pilings and beams, that hold everything together). The BMC mould is very robust, light and durable which makes it the preferred material to build giant bridges with a lot of weight on them.

Whereas SMC is a molding process using compression of the material into a mold, FRP also known as fiberglass reinforced plastic (a fabric) is assembled by layering sheets of resin into position one on top another. Due to these differences, SMC exhibits increased strength and stiffness as compared to FRP. This makes the Belite material excellent for constructing structures that need to bear high loads. What's more, tray resin mold typically outperforms FRP in terms of durability since its resistance to weather and chemical damage are superior.

The SMC based technology is still underneath and will follow the path of technological advancement as it gets better. A quite inspiring area in development is the rise of renewables where materials are concerned. To address this researchers are now developing novel SMC with plant-based materials and biodegradable resins. At the same time, it is likely to reduce its environmental impact in building structures as a result which would make TQ SMC Moulds more environmentally sustainable.

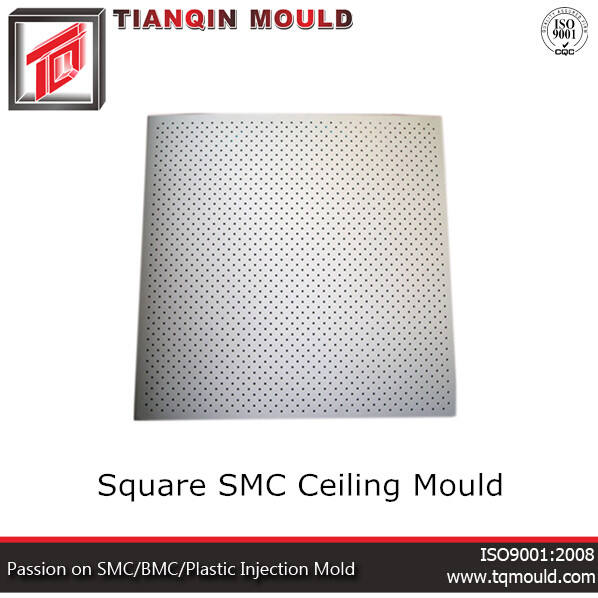

Tian Qin will develop different plans for each of the projects to ensure that the product is of high quality and produced in the shortest amount of time. Before Sheet molding compound, we use professional equipment to ensure that the dimensions as well as the structure are correct so that the buyer receives the item without issue.

TianQin has its own workshop, which is 8,000 square metres and the Sheet molding compound it owns and a expert team, that has been thoroughly trained in the field of moulds for over 20 years and has unique knowledge regarding mould design and production in order to provide customers with the most effective solution.

The company has been awarded ISO, CE and other certificates. The warranty for the company is 12 months beginning on the day the client receives the product. We will be able to resolve issues Sheet molding compound, even if a issue lasts longer than 12 months.

TianQin provides plastic products and moulds. There's Sheet molding compound to the product categories, and the most comprehensive customer support is available for bespoke design and custom-designed solutions. Let customers have unique design and the best capacity output.