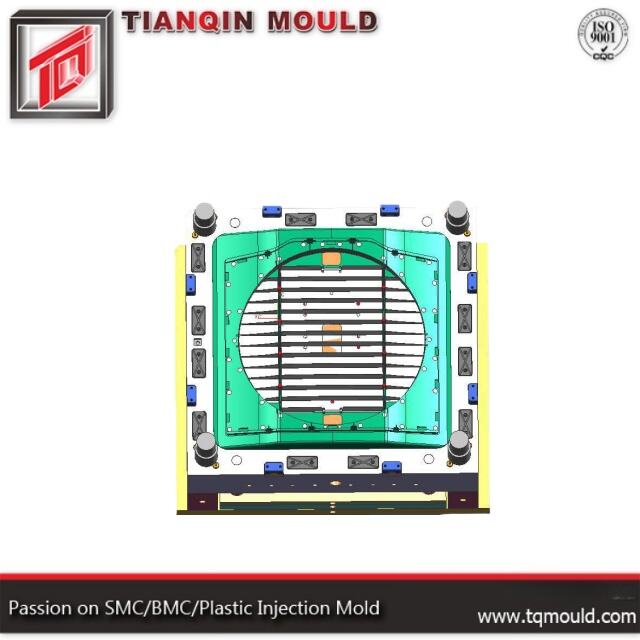

Various components that work in concert form an SMC cooler mould. TQ air cooler mould has three primary parts—outer casing, cooling ribs, pipes. The outer section is like the body of an automobile, housing everything inside it. The cooling fins are tiny fingers that slap the air more scattered. Pipes, like veins, transport chilled water through the mould to ensure a cooler environment.

SMC cooler moulds are very crucial for temperature control and prevent over-heating. When they become too hot, they may stop functioning altogether or even get damaged. SMC cooler moulds make it cool and in good running condition. SMC cooler moulds are crucial for cooling systems to function properly.

SMC cooler mould selection is categorized based on the cooling system size and required cooling power. Where the mold is going to be used and what is going to cool the mold also need to be considered. If you choose TQ air cooler mould with lots of cooling fins and pipes to cool a big machine in a very hot factory. You should also make sure that the mould should be made of the hard materials which can resist high heat and heavy wear.

The SMC cooler moulds utilized in the factories are of many benefits. One of the biggest benefits is that they keep machines and equipment running smoothly and avoid overheating. This can save companies money on repairs. The SMC cooler moulds also allow cooling systems to run more efficiently, lowering the energy cost of consumption, while being more environmentally friendly. Overall, SMC cooler moulds enable factories to remain cool and produce at a high rate.

There should be regular maintenance to make sure cooler TQ smc mould are in good condition. It also includes cleaning the pipes and cooling fins, checking that there are no leaks or damage, and that all of the parts are functioning correctly. Fix any issues you find immediately to avoid causing more damage. SMC cooler mould will cool things down and assist with smooth operation for a long period if well maintained.

TianQin is home to its SMC cooler mould workshop that covers more than 8,000 square metres as well as the processing equipment it owns, and a experienced team that has been deeply cultivated in the field of moulds over the past 20 years, and has unique insights on mould design and manufacturing, as it can provide clients with the ideal solution.

The company has achieved ISO, CE and other certifications. The SMC cooler mould for the company is 12 months starting at the time the buyer receives the item. We will still respond positively to problems after sales even if the problem exceeds 12 months.

Tian Qin develops SMC cooler mould for each project, in order to ensure that the quality is maintained and production occurs within the shortest amount of time. Prior to shipment, we make use of professional equipment to ensure that the dimensions and design are accurate to ensure that the customer receives the goods without any issues.

TianQin offers plastic products and moulds. The categories available are infinite and we provide the best support possible to SMC cooler mould as well as customized designs. Customers can design their own style with the best output.