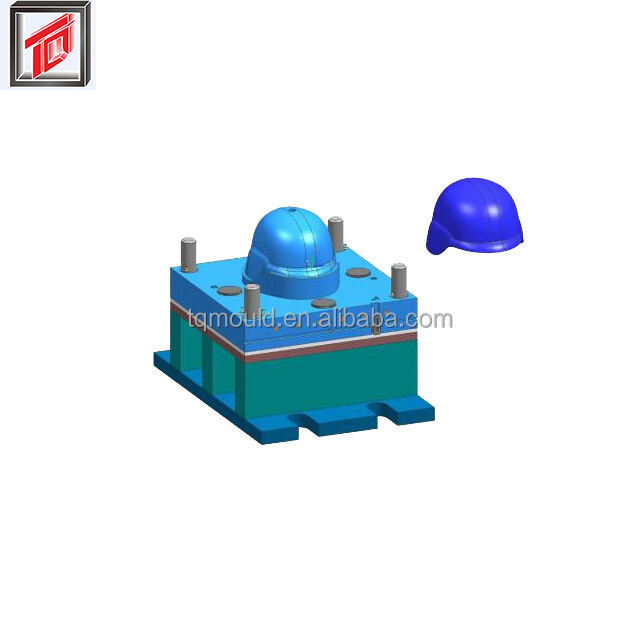

Introducing, the latest must-have item for all helmet manufacturers - the High Quality New Hot Sale Helmet Mold from TQ. This innovative product is perfect for creating top-of-the-line plastic helmets that are both durable and stylish.

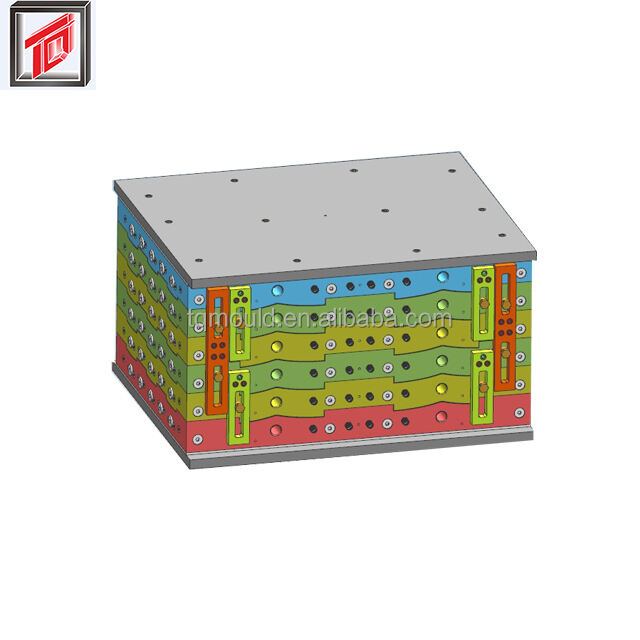

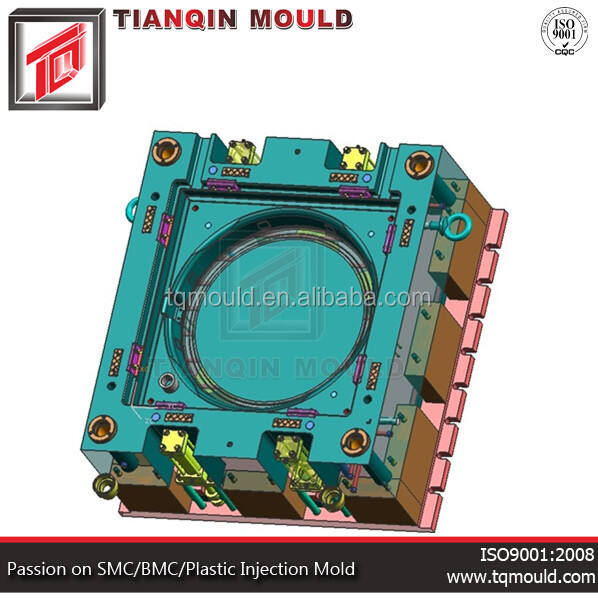

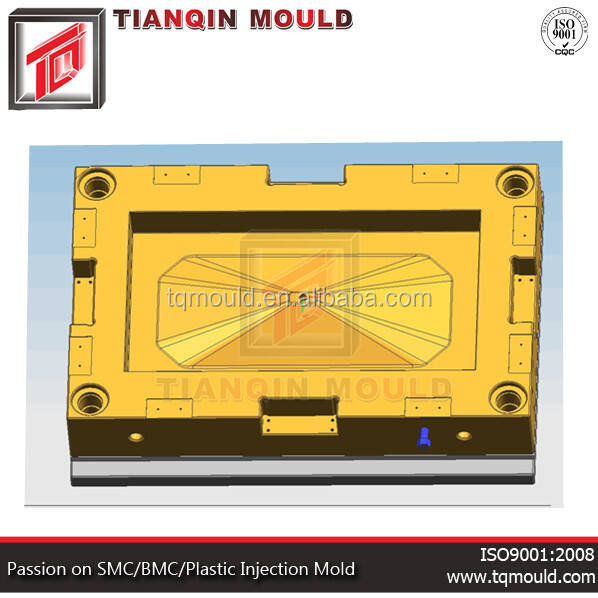

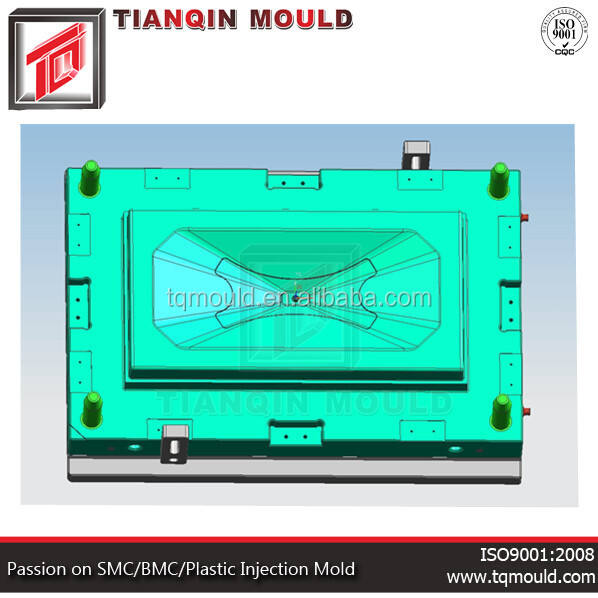

Crafted with precision and care, this helmet mold is highly polished to perfection, ensuring a smooth finish on every helmet produced. Made from a high-quality composite material, this mold is designed for maximum durability and longevity, making it a wise investment for any manufacturing business.

One of the standout features of this helmet mold is its innovative compression technology. This ensures that each helmet produced is made with the highest level of accuracy and consistency, resulting in a product that is both safe and reliable for users.

In addition, the TQ helmet mold is designed with ease of use in mind. With its user-friendly design and simple operation, this mold is perfect for both experienced manufacturers and newcomers to the industry. Whether you're looking to produce one helmet or hundreds, this mold is versatile enough to handle any production volume.

Not only is this helmet mold of the highest quality, but it is also competitively priced, making it a cost-effective option for businesses of all sizes. With the TQ brand behind it, you can trust that this product is made with the same attention to detail and commitment to excellence that has made TQ a trusted name in the industry.

Whether you're looking to upgrade your current helmet mold or are just starting out in the manufacturing business, the High Quality New Hot Sale Helmet Mold from TQ is the perfect choice for all your helmet production needs. Don't miss out on this opportunity to take your business to the next level with this top-of-the-line product. Order yours today and see the difference that a high-quality helmet mold can make in your production process

Taizhou Tianqin Mould & Plastics Co., Ltd

High Quality New Hot Sale Helmet Mold Highly Polished Plastic Helmet Composite Compression Mould

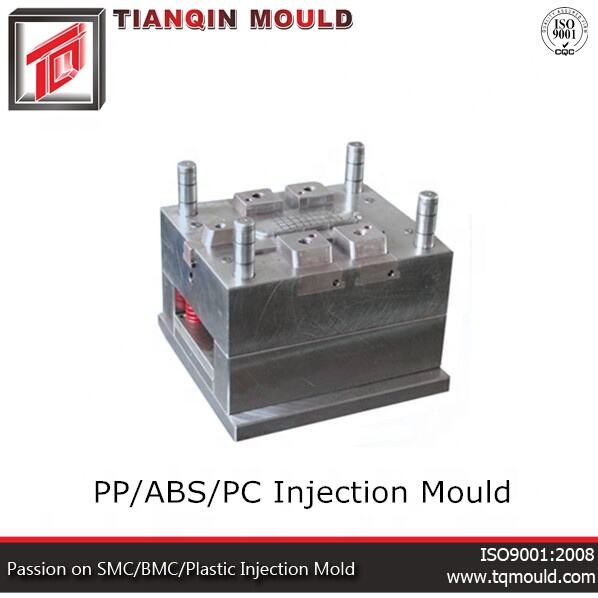

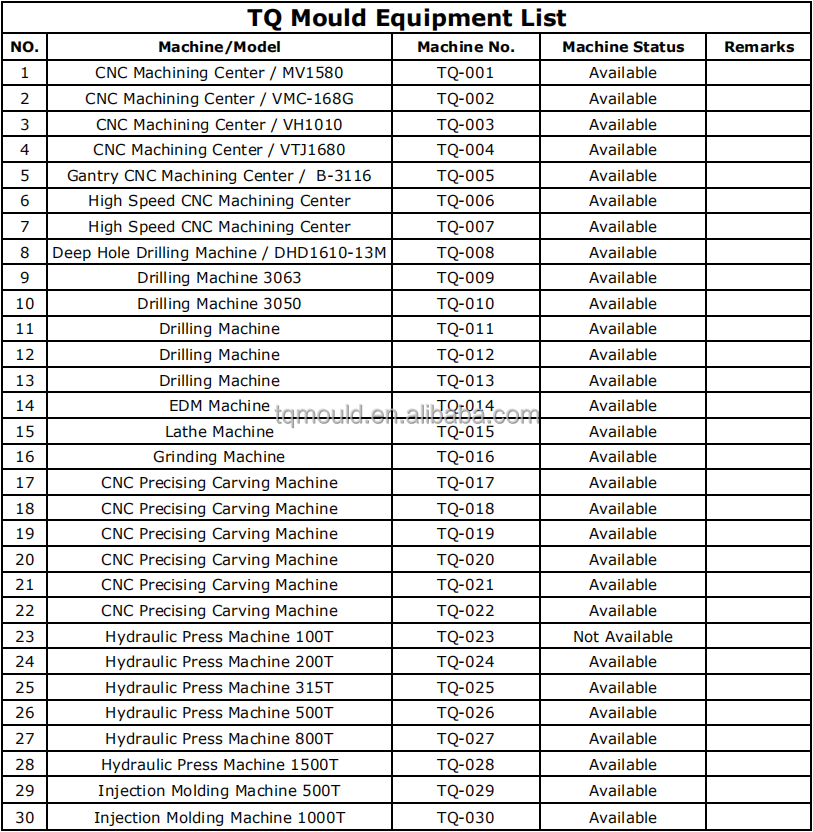

With over 15 years OEM & ODM experience, TQ Mould Co., Ltd. Is a professional manufacturer and exporter in zhejiang Taizhou Huangyan, We export not only abroad but also domestically. Specialized in designing and manufacturing high-quality plastic injection mould. More than 25 sets of equipment for mould processing, manufacturing, trial and parts production

Including Milling Machine, Cutting Machine, CNC Machine, EDM Machine, Grinder Machine, Drilling Machine, Hydraulic Press Machine, etc

We can also provide 3D design, mold making and bulk production service for your company

Main Compression and Injection Mould Category:

1. Auto parts mould: heavy-duty truck bumper, instruments panel, car roof, door panel, trunk cover, sky shade, engine hood, air conditioner shell, battery box, etc

2. Kitchenware & sanitary ware mould: bathtub, shower room, shower tray, waterproof plate, toilet lid, sink, table top, melamine tableware, etc

3. Electronic appliance mould: electric switch box, power distribution box, electric fan cover, meter box, cable branch box, cable holder, insulator, insulating cover, etc

4. Sports equipment mould: basketball board, table-tennis table board, FRP chair, etc

5. Products mould: helmet, armor, shield (PE, Kevlar), magazine, etc

6. Other construction & industrial supplies mould: water tank, manhole cover, trash can, dustbin, industrial helmet, etc

| Name | Description |

| Mould Material | 45#/ 50# /P20 /H13/ S136 /SKD61/ etc |

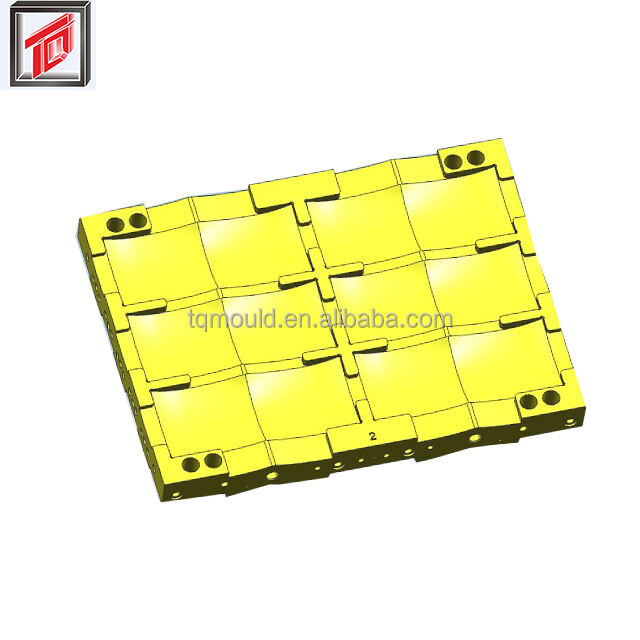

| Cavity | Single/ Multi |

| Runner | Cold / Hot |

| Design Software | UG / CAD / PORE /ect |

| Mould Life | 10,0000 - 1,000,000 shots |

| Delivery Time | 35-50 days |

| Specification | As the client's requirements |

Q1: Could we get the sample for reference

A1: Glad to send samples for your inspection, but need to pay the sample (depends on product's value) and the express fees, hope understand

Q2: How long the product will be ready for shipment

A2: Depends on the product's specification and quantity. The time of delivery is different. In general it will take 35-45 work days

Q3: How can we guarantee quality

A3:

(1) Strict detection during production

(2) Strict final inspection on products before shipment and intact product packaging ensured

Q4: What is your terms of payment

A4: T/T, L/C, PayPal, and can be negotiated

Q5:How to solve the quality problems after sales

A5:

(1) Take photo or video about the problems and send to us.

(2) Send back the defective products to us if necessary. Feedback the solution to you once confirmed

Q6: Can we make our logo on the products

A6: Sure. Please contact us, we will reply within 12 hours. Thank you very much

Our professional sales team is always waiting for your consultation.