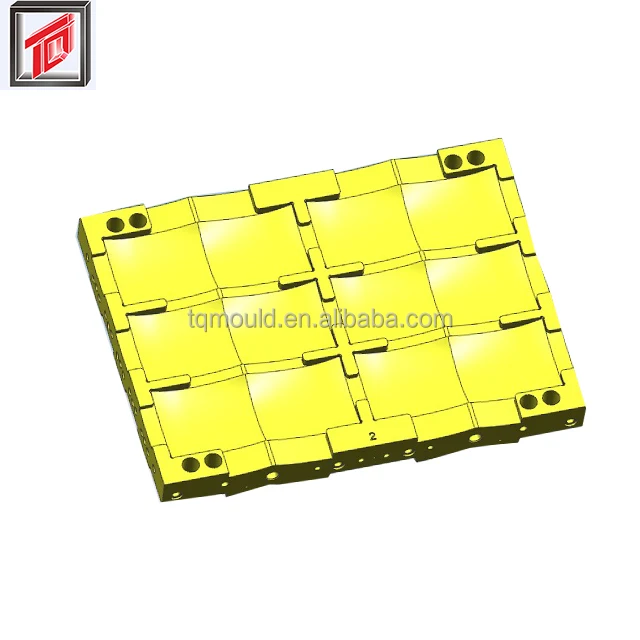

That said, thickness is incredibly important when cutting UHMWPE plates. These are formed of this special kind of extremely strong and versatile plastic that we use for all sorts of things, such as building equipment for factories, making parts for trucks, even wear strips or liners (just to name a few). TQ understands that maintaining the right thickness ensures that no two products are ever the same. This is called thickness control. Plates that do not match in thickness may not perform as well or last as long. This is important for wholesale customers, who want their products to be of a high quality. They do not want to purchase things that break easily or are inappropriate for their needs.

UHMWPE Plate Mould Thickness Control - What is it and Why Should Wholesale Purchasing Agents Worry About It?

Thickness control in UHMWPE plate moulds month. Checking the thickness of every single plate as it is made. The mold has to be perfect when TQ is producing these plates. Changes in thickness, no matter how slight, can create trouble. Consider purchasing a dozen cookies. If some cookies are thicker than others, then it will lead to doughy in some places and possibly too chewy elsewhere. The same principle applies for UHMWPE plates. These plates are what wholesale buyers order, and they assume that all the plates will be the same size and strength. If one plate is thinner, it can chip or wear down fast. This can result in unhappy customers and costly returns.

TQ takes this very seriously. We use special machines and processes to maintain that thickness across all our plates. We handle each of the matters cautiously and we correct the issues at once if any. Our customers believe that they are buying durable and resistant plates that are loyal to their work. The points of matters are the companies that utilize these plates need to rely on the guaranteed function each and every time. In case our TQ thickness is reliable, it also means that the buyers can buy it with no risk. In addition, it supports the creation of a good relationship with the clients, as they realize that they can put their trust in us to deliver high-quality products.

How to Control the Thickness of UHMWPE Plate at High Precision is Crucial for Good Quality Products

The ideal thickness of UHMWPE plates is the right direction to take. To begin with, we have to ready the machinery. Calibration of machines is done at TQ. This implies that they are tuned in such a way that everything works out. Once the plates are made we have control over an example of the production. The measuring tools help us to call out the problems at hand. So far as everything is fine, we can produce more plates of the same thickness.

Staff training is another essential article. TQ makes sure all people are aware of how to operate the machines, inspect over merchandise. As one will have an understanding so will be the earlier concern about issues. We only ask them to make a noise when something does not work. Sometimes an itty error may take place in the production process. Early detection may rescue the situation.

Lastly, we keep on improving our techniques. TQ believes that technology can help our processes. Finally, we can also use new and improved tools and techniques to achieve even more effective thickness control. Increased technology leads to increased uniformity of products. It is a victory to our wholesale buyers because it reduces the mistakes nobody would want to be caught with when your plates come. In general, all these techniques can enable us to create a fine product to ensure that every UHMWPE armor plate suits you.

Thickness Variability and Its Impact

When using UHMWPE plates, thickness is very important in the production of products. It is tough and durable material, it has been used in a number of ways medical equipment, armor and, well, even skateboard ramps. That is all well enough, but in case those plates differ in thickness to any extent, then such a mode of working may be a liability. As an example, when one plate is thinner than another, then it can be easily broken or worn out. This may as well create quality and safety issues to the final customer. We understand here at TQ that it is important to maintain the evenness to enable us to make good products that people can count on. And when the firms do not hold thickness very fine, they may end up developing weak areas in their products. This is risky especially when it comes to such products as the prosthetics or safety equipment. When the customers are buying an item that should be strong and reliable, they would wish to believe that every piece will be of the same quality. and in case the thickness is not uniform, there may be much frustration. That is why, thickness in production is, hence, controlled in front stage. At TQ we weigh our plates to ensure that they are all the same thickness. Having no thickness variation, we will be able to make our customers feel safe and confident about our products.

UHMWPE Plate Thickness Control for Competitive Advantage - What Buyers Must Know

The new purchasers of UHMWPE plates would know that they should have thickness control in case they wish to attain high quality. Consumers are also supposed to think of the thickness of a plate when selecting one. A heavier plate may, though need not, be stronger but, of course, the converse of some models. When a plate is made carelessly then it tends to cave in and even when it is a thick plate, it fails. The buyers need to therefore seek companies like TQ that focus on thickness control. Preciosity is a virtue and the fact that we promise to weigh every plate ensures that the customers are aware of what they are purchasing. They are able to acquire us and have the feeling that our products would last. Moreover, the ability to regulate the thickness makes buyers win. Companies as far as you want to use plates with the same thickness, it makes them better products. For example, tough materials play a very important role in the construction. Hence, in case workers used plates of different suppliers who might differ in thickness, then it might add weak points to the building. This may not only be expensive, but also unsafe. Choosing TQ in the purchase of the UHMWPE sheets, the purchasers would ensure that they had a good partner. In this manner, they will have the opportunity to provide resilient and reliable products to their respective customers. The existence of competition among businesses is one of the things that help them grow and thrive. It is not such a minor detail that the thickness control was gigantic.

How Thickness Control of UHMWPE Plate Makes it Durable and Performance Based for Applications

Strict limits of thickness of UHMWPE plates are not just concerning compliance, in reality, this assists ease of better products. The plates work also in cases where the plates are uniform. That is to say they are more powerful and last longer. Smaller plates, are likely to be lighter in other industries like health care, but they cannot endure as much abuse. In the case of medical devices manufactured using UHMWPE plates, the physicians have to be assured of the reliability of the plates. At TQ we ensure that we use the proper thickness on our plates since it will operate well. The plate mould are strong enough to withstand the heavy and continuous use. They will also withstand high temperatures and heat treatments that are excessively high. It is significant in machines where the pressure and the load are big. And besides that, the more efficient the work of the UHMWPE plates, the more satisfied the customers will be. Those are the entire spectrum of individuals who are involved in sporting activities up to the engineers who are involved in the building. The users can never be satisfied until they get the appropriate product to use that is user-friendly. As TQ, we are pleased to provide you with plates that help you reach the maximum productivity as far as the thickness is regulated. The final outcome is that we all end up using safer and long lasting products. Control of thickness is one of our concerns; hence, it is not only that we are selling plates, but also serving many applications that can be stronger and more even.

Table of Contents

- UHMWPE Plate Mould Thickness Control - What is it and Why Should Wholesale Purchasing Agents Worry About It?

- How to Control the Thickness of UHMWPE Plate at High Precision is Crucial for Good Quality Products

- Thickness Variability and Its Impact

- UHMWPE Plate Thickness Control for Competitive Advantage - What Buyers Must Know

- How Thickness Control of UHMWPE Plate Makes it Durable and Performance Based for Applications