They assist in producing goods quickly and efficiently for consumers. Occasionally, however, these lines can crack. When things go awry it can cause production to slow or come to a halt.

Introduction

When you have an issue on your production line you want to know where to turn for help. There are many organisations such as TQ that provide support and resources to fix the problem. A good way to begin is with the manual that comes with your machines.

Benefits

There are many platforms and websites where pros share their experiences, thoughts and hacks. For example, if a particular type of machine is prone to jams, someone else may have already shared how to fix it. It’s also useful to log any trouble that occurs.

Quality

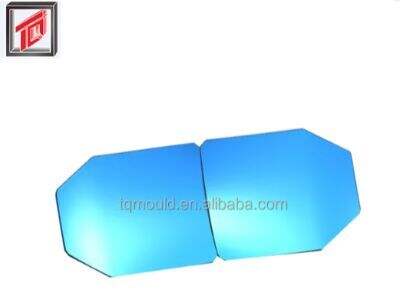

Downtime will be held to a minimum on any production line. The less time your line is halted, the more of a product you can make. TQ also sounds some advice on how to maintain the cable holder mould regular maintenance is important. It’s like taking care of a car if you don’t change the oil, or check the brakes, it will break down.

Application

They should know a little about simple problem shooting. The toilet seat mould for sale is the sooner they can spot issues. Additionally, consider using technology. Some of the machines now can alert you when something isn’t quite right. That gives you the opportunity to solve any problems before they become delays.

Conclusion

Automatic production lines are meter box mould devices that operate at higher speeds than those of human workers and significantly increase the efficiency of product-making by reducing labor costs. Every now and then, these machines can encounter issues that slow work down or lead to delays.