TQ Products using sheet moulding compo When it comes to making items, und have many benefits. To start, they can be formed into so many different shapes and sizes. This makes them super versatile for so many things! They can be used as small components for machinery or large assemblies of furniture, for example. mold for resin tray too are very sturdy and will withstand a large amount of wear and tear over the years. This is critical when crafting the components which go into products such as heli-copter elements and devices that should perform perfectly pertaining to extended durations with out suffering breakage or perhaps wearing. Sheet moulding compound products are also lightweight, which is another great thing about them. But this is a very beneficial to carry an object, in which the light product you can easily & with less coast This leads to reduced shipping costs for companies. Due to their water, chemical and photo stability these products can also last even longer across the full range of environments. All these features make them perfect for other products that will be used outdoors and need to stand up against weather.

One of the best things about sheet moulding compound by TQ products is that they are equally versatile. They can be used to create anything from car parts and outdoor furniture, as well come in a variety of colors. helmet mould manufacturers means manufacturers can produce all sorts of crazy creative designs with these products. An example might be a manufacturer that produces attractive outdoor seating in bright colours and make them durable enough to survive over multiple seasons. FMVSS 321 CFR Part 571“It is no longer just governed by its inherent high impact resistance but also its versatility in being able to placed on the front and rear, keeps it from receiving a greater risk rate for internal organs,” Rosenbloom said. This means, they can withstand a lot of wear without ruining or breaking them. It is even more true for outdoor furniture and products that get exposed to different temperatures, rain or sun. They are relatively long-living as well, spanning often multiple years meaning a pretty good bang for buck both from the manufacturer and users perspective.

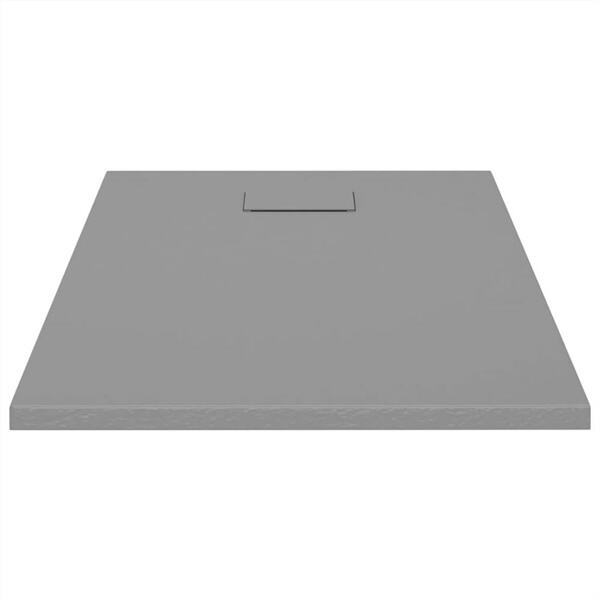

Because sheet moulding compound products of TQ are capable of being shaped in many different ways, manufacturers can utilise them to fabricate bespoke car parts that seamlessly fit cars according to their own unique model. tray resin mold way manufacturers can produce special parts that enhance the appearance and performance of cars. Furthermore, it not only allows manufacturers to produce parts exactly as per the requirement but also, save money in long run producing less wastage materials.

Finally, sheet moulding compound products can actually save businesses some money in a few different ways. They provide an inexpensive means of compliance to manufacturers because they are high strength and low weight. safety helmet mould allows companies to manufacture high-quality items for much less money. Custom sizes may also be molded; this lowers the amount of waste materials in production. It cuts back on waste and saves money for needed materials.

Not only that but because they're lightweight and don't take up much shipping space, these items could save a business transport money. This ultimately results in lower costs of delivery, one natural aspect that a business seeks to gain. tray mould resin are also lightweight and simple to assemble, so labor costs will be less after some time. In all, these advantages are what really makes the sheet moulding compound a dream product for so many businesses looking to make their production process more efficient and cost effective.

TianQin provides plastic products and moulds. There's Sheet moulding compound products to the product categories, and the most comprehensive customer support is available for bespoke design and custom-designed solutions. Let customers have unique design and the best capacity output.

Sheet moulding compound products will develop different plans for each different project to ensure that the product is of high quality and produced in the shortest amount of time. We will make use of professional equipment prior to shipping to examine the dimensions and the design to ensure that the customer gets the products in perfect condition.

The company has Sheet moulding compound products, CE and other certificates. The warranty period is twelve months from the date of receipt of the products from the buyer, however we will respond positively to any issues after sales, regardless of the length of 12 months. Our goal is solving any concerns of the client.

TianQin is home to its Sheet moulding compound products workshop that covers more than 8,000 square metres as well as the processing equipment it owns, and a experienced team that has been deeply cultivated in the field of moulds over the past 20 years, and has unique insights on mould design and manufacturing, as it can provide clients with the ideal solution.