Did you know how plastic pots are manufactured? And that is all thanks to a process called mould making! All about mould making Mould-making is an important art that involves casting a hollow shape called the “mould. This TQ mould will then fill with liquid plastic. Once the plastic cools and hardens, we remove it from your mould and create a new plastic container.

Mould makers start their work by designing the place to form they want. Its like a design of the mould that they wanted to make since, because in this way it gets easier for them know what size and shape do their smc mould mold needs. Once they have a design, the mould is built from raw materials. Crafting a mould that functions correctly is quite difficult and requires much skill. Then, the plastic container producing and extruding fun can get started!

To some extent mould making is an art but actually there is science behind the mirror of this creative part. When mould makers sample a good quality eight layer blowing machine, it is important to use the right materials and make careful measurements. For example, they have to take into account specifics like how hot the plastic will be when poured in the mold and how fast it is about cooling. If the helmet mould manufacturers mould is not made from proper material or has been mistreated then plastic container that comes out of it may also be fragile, other than might have discrepancy on part design.

Producing the plastic containers is a job that has to be done and we use them in almost every day but they are also something where industry changes and enhances constantly. Technology is evolving and there are new materials and methods that have been created to make plastic containers. Some manufacturers, for instance, are now turning to materials that degrade in nature. This TQ means that these materials are more eco-friendly because they do not become land fill pellets!

Other manufacturers are using safety helmet mould different technology for create moulds, such as exciting 3D printing. The TQ process is faster and frequently more precise than conventional mold making. 3D printing allows mould makers to create difficult shapes unsupported. As we are always discovering new and improved ways to create plastic storage containers, in the future they will become stronger, better for our planet and even more versatile.

In making the moulds better, most of these institutions will be keen to ensure that they maintain integrity and thus carry out several quality control checks while in process. And that tray mould resin means they rigorously test the moulds before these are implemented to craft plastic containment vessels. Without creation of best mould plastic containers will be either harmful to use or are relegable after few uses.

With the growing number of people becoming environmentally conscious it is vital that plastic container and lid manufacturers produced product which is safe for us as wells our planet. With the bumper mould use of new materials and innovative methods, plastic containers can supply us with quality products on one hand while they help preserve our ecology as well.

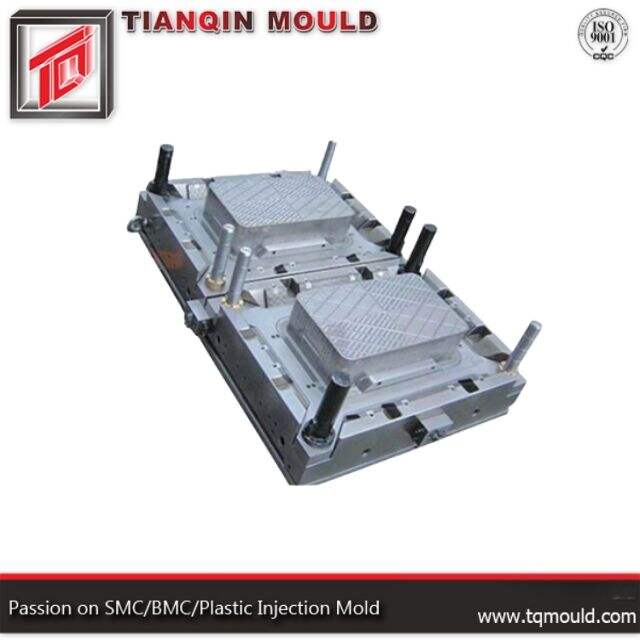

TianQin currently provides moulds as well as plastic items. There is no limit to the Plastic container mould and we offer the best possible support for a custom design and customised solutions. Let customers have unique design and the best capacity output.

The Plastic container mould has been awarded ISO, CE and other certifications. The warranty duration is 12 months from the date of delivery of the products from the buyer, however we'll be ready to address any problems after-sales, regardless of whether they extend beyond 12 months, aiming at solving the concerns of the client.

Tian Qin will develop different plans for each of the projects to ensure that the product is of high quality and produced in the shortest amount of time. Before Plastic container mould, we use professional equipment to ensure that the dimensions as well as the structure are correct so that the buyer receives the item without issue.

TianQin's factory has an area of Plastic container mould. it has its own processing equipment and a team of experts who have worked in the mould industry for more than 20 years. They can provide customers the best solutions.