The smc compression molding is key for producing strong and safe helmets that help protect our heads. Let’s find out how these special molds are made and why they matter!

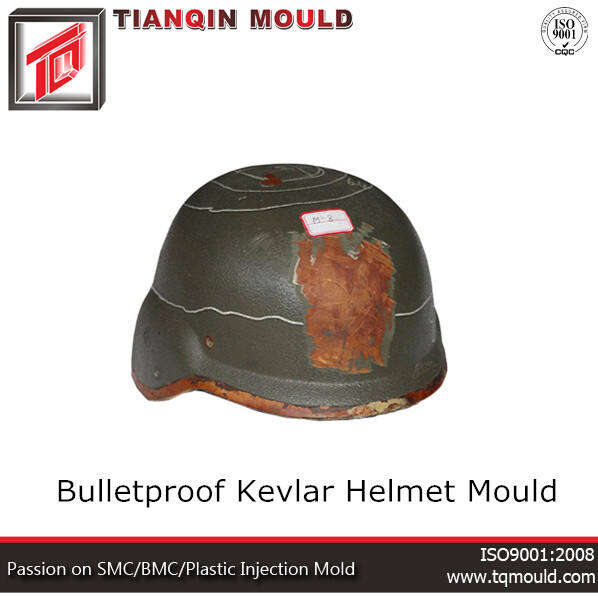

The process begins with design of a Kevlar helmet mold. Engineers painstakingly deliberate over how the mold will appear and what form it must take. Then, when the design is complete, they use special machines to cut the mold from a huge piece of metal. That takes time and attention to ensure that the mold is just so.

Once your mold is prepared, it is time to create the true helmet. Layers of Kevlar fabric are then added inside the mold, and a special resin is used to cause it to set hard. The mold is heated so the materials will bond together and create a solid shell. When the helmet has cooled, the mold is opened and the helmet is removed and inspected for errors.

And it is essential that we build Kevlar helmets properly so that they can be effective in protecting our heads in the event of accidents. If a mold is not made just right, for example, then the helmet may not be strong enough or safe. If we have good molds and put things together in the right way, then we can be confident that the helmets will keep us safe.

Fabricating smc moulds is a science, an engineering. The construction material, however, must be durable and capable of limiting impacts yet remaining lightweight, non-restrictive and comfortable to wear. Engineers are examining Kevlar and other materials to determine how to produce helmets — that are able to run with — which are both safe and wearable.

Helms form Kevlar molds Exert not you, safety-yours significantly. If we can make precise, strong molds, then we can make helmets that save lives in accidents. Without these molds, it would be significantly more difficult to manufacture helmets that are strong enough to keep our brains safe.

TianQin is home to its Kevlar helmet mold workshop that covers more than 8,000 square metres as well as the processing equipment it owns, and a experienced team that has been deeply cultivated in the field of moulds over the past 20 years, and has unique insights on mould design and manufacturing, as it can provide clients with the ideal solution.

TianQin currently provides molds and plastic products. The categories of products available are unlimited, and we offer the best support possible for customized solutions and custom designs. Customers can get a Kevlar helmet mold that is the most efficient.

The company holds ISO, CE and many other certificates. The warranty for the company is 12 months, Kevlar helmet mold from the date the customer receives the product. However, we'll be able to resolve after-sales problems even if the issue is beyond 12 months.

Tian Qin develops different plans for Kevlar helmet mold project, in order to ensure quality and production in the shortest time possible. We use high-end equipment prior to shipment to verify the dimensions and the design to ensure that the client receives the product in perfect condition.