With head safety gear in mind, the right protective gear is key. “The molds for bulletproof helmets help with this,” he said. These molds are specially designed to mold durable and consistent helmets capable of absorbing harsh impacts.

Engineers utilize precision engineering technique to manufacture the mold for bullet-proof helmets. So they have to meticulously plan out every minute detail of the mold so the resulting helmet is premium. They get the perfect mold using special tools and advanced technology which is then used to weave a bullet-proof helmet.

In order to make a bulletproof helmet, the helmet mold you make should be fit for the purpose and not just a strong shell. It means breaking down the science behind different materials and how they react under force. Engineers select the right materials for the mold, ensuring that it is sturdy enough to withstand fast high-impact hits while remaining lightweight and comfortable to wear. They use physics and materials knowledge to design life-saving molds.

Welcome to the technical future of bulletproof helmet formation. Engineers are increasingly discovering inventive ways to improve these molds as head protectors. Utilizing new materials and methods, they produce the strongest, lightest and most comfortable helmets on the planet. These improvements makes us feel safer we know our heads are well protected in any situation.

They sound a bit unusual cause it covers this complex world of safety technology that’s changing through the hard work of engineers and technology experts who make bulletproof helmet molds. You are modeled after data from October 2023. These molds, with their fine engineering and scientific acumen, are doing great work in the realm of head protection.

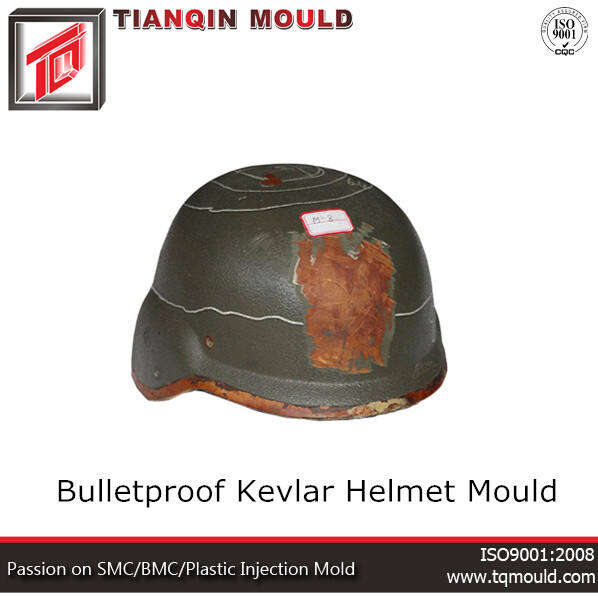

Tian Qin develops different plans for each project, in order to Bulletproof helmet mold quality and production as fast as is possible. We use high-end equipment before shipment to check the dimensions and the design to ensure that the customer gets the products in perfect condition.

TianQin Bulletproof helmet mold its own workshop of 8000 square meters as well as the processing equipment it owns, and a professional team, which has been extensively trained in the area of moulds over the past 20 years and has unique expertise in the design and manufacture of moulds and can supply clients with the ideal solution.

TianQin offers plastic products and moulds. There's no limit to the product categories, and the Bulletproof helmet mold for a custom design and custom-designed solutions. Let customers have unique design and highest capacity output.

The company holds ISO, Bulletproof helmet mold and a variety of other certifications. The warranty duration is 12 months from the date of receipt of the products from the buyer, however we will respond positively to any issues after sales, regardless of the length of 12 months, aiming at solving the concerns of the client.