Well, first up let's have a little chat about bmc compression molding. It’s a unique way of creating strong, durable products. The method utilizes a material known as Bulk Moulding Compound (BMC) which is injected into a mould under high pressure and with heat. This makes the material fit the shape of the mould and also become hard.

The good thing with BMC compression moulding is that you can produce complex shapes and sophisticated designs. The material can be bent without weakening. This is why BMC compression moulding is ideal when it comes to manufacturing a product with additional features.

Another advantage is that bmc mold results in very strong products. They’re tolerant of heat, chemicals and impact. This makes them capable of more extreme use, and more durable over time, as they will maintain their original shape without breaking. This toughness also helps to explain why BMC compression moulding is so popular for manufacturing parts that demand reliability.

In addition, BMC compression moulding contributes to making products aesthetically pleasing by offering them a smooth surface. Rubbing against fewer rough areas may reduce a dent or damage. That means products produced this way can remain in good condition over time.

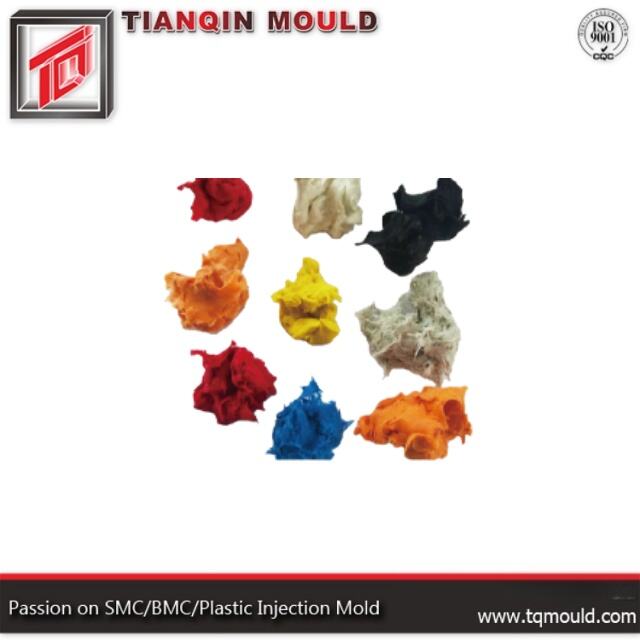

To excel at BMC compression moulding, there are few key things to bear in mind. Step 1: Select the Best BMC Material for the Product You Want to Create. Various BMC materials have various properties, and select the right one is the key to produce good parts.

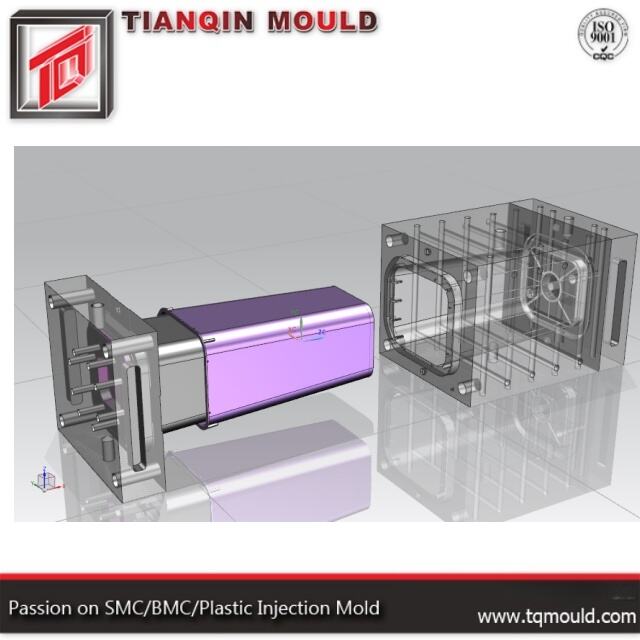

Second, the mould has to be designed properly to take the heat and pressure applied during the process. A good mould ensures that the products are precise and match well with each other. Keeping the right temperature and pressure throughout this process is also key, so the BMC material cures properly.

BMC compression moulding can be used in a variety of industries. For instance, the automotive industry uses it to produce lightweight, strong parts for cars. The electrical industry uses it to make heat-resistant parts. And the aerospace business has used BMC compression moulding to create strong parts for planes and rockets.

The company has achieved ISO, CE and other certifications. The BMC compression moulding for the company is 12 months starting at the time the buyer receives the item. We will still respond positively to problems after sales even if the problem exceeds 12 months.

TianQin BMC compression moulding offers molds as well as plastic items. The product categories are unlimited We provide the highest level of support for customized solutions and custom designs. Allow customers to have a distinctive designs and the highest capacity output.

TianQin's factory has an area of BMC compression moulding. it has its own processing equipment and a team of experts who have worked in the mould industry for more than 20 years. They can provide customers the best solutions.

Tian Qin develops different plans for each project to guarantee quality and BMC compression moulding within the shortest amount of time. Before shipping, we use professional equipment to ensure that the dimensions and design are correct to ensure that the client receives the product with no issues.